Category Archives: Customer Reviews and Building Projects

Construction Company Kudos

You don’t need to specialize in steel building construction to put up a Worldwide Steel Building. Just ask Scott Tallman, president of Tallman Construction, a general contractor in Idaho Falls, Idaho. “It’s a user-friendly solution that doesn’t require any special equipment or tools,” he says. “My guys had no problem putting it together. Everything went very smoothly from start to finish.”

Scott designed and constructed two steel buildings for Sun Rain, a client of his that grows and distributes a variety of potatoes. One of the structures required a constant temperature between 48 and 52 degrees, meaning a poly-foam insulation had to be applied to the entire building. Fortunately, Scott was able to do so thanks to the versatility of the Worldwide Steel product.

Beyond versatility, Scott says he chose Worldwide Steel over other manufacturers because it offered both better pricing and better service. It’s why he’d use Worldwide Steel in the future along with recommending them to others. “We definitely had a great experience with the product and the staff. I’d work with them again in a heartbeat.”

Scott Tallman is one of many satisfied Worldwide Steel Buildings customers. Learn what others have to say by visiting worldwidesteelbuildings.com. Then try out the free 3D Design Tool to map out plans for your steel building.

Got Questions? We Have Answers.

If David Olsen had a question, Worldwide Steel Buildings had an answer. It’s why the do-it-yourselfer was able to successfully assemble his own multi-purpose steel building on his property in Boulder, Colorado. “Whenever I needed help during construction, Worldwide Steel was always there for me,” says Olsen.

Olsen required assistance early on after his local municipal building department asked him to modify foundation plans. He reached out to his Worldwide Steel customer service representative who quickly provided adjustments to meet requirements. Later on, Olsen experienced some minor material snafus that were easily remedied by Worldwide Steel.

“Their responsiveness made a world of a difference,” notes Olsen. “I was able to count on them throughout the project.”

Olsen leveraged one of Worldwide Steel’s predesigned packages and utilizes his 2,000-square-foot facility as a garage, shop and storage facility. He wouldn’t hesitate to recommend Worldwide Steel to others. “They offer a hard-to-beat combination of product and service. I’m really happy about how my building turned out.”

Find out what other customers have to say about Worldwide Steel Buildings by visiting worldwidesteelbuildings.com. Then try out the free Worldwide Steel Buildings 3D Building Designer Tool.

Spark Your Imagination

Get a clearer picture of the steel building in your future with a little help from the satisfied customers of Worldwide Steel Buildings. Now available on our website are design examples created by our customers (with our popular 3D Building Design Tool) that served as the springboard for the steel building of their dreams.

You’ll feel inspired to take your design to the next level by viewing the plans of others whether you’re thinking of building a garage, workshop, house, barndominium or commercial building. Worldwide Steel Buildings hopes to help people get over the design hump by simply sharing the work of others.

“Sometimes it just takes a little spark to the imagination to complete a building design,” says Jeff Snell, president and CEO of Worldwide Steel Buildings. “And what’s great about our 3D design tool is that it provides a clear vision of the buildings that’s swirling inside the heads of our customers.”

So take a look-see at the other building designs today to get inspired for tomorrow. Go to https://www.worldwidesteelbuildings.com/design-examples/.

Try out the free Worldwide Steel Buildings 3D Building Designer Tool.

Customer Success Spotlight: Russ & Ranae’s New Shop

We take pride in the products we manufacture, and how they help our customers meet not only a practical need for space, but also achieve their goals for their business, family, or lifestyle. That’s why we love hearing from customers like Russ and Ranae about how they’re using their customizable steel building:

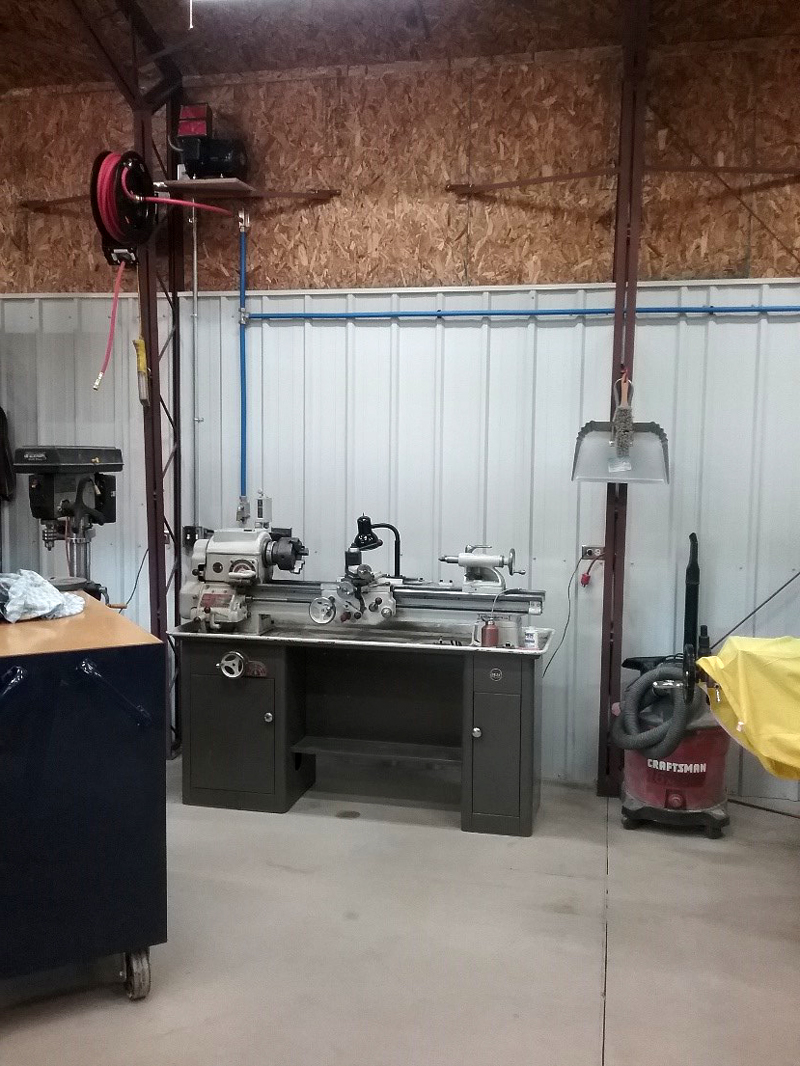

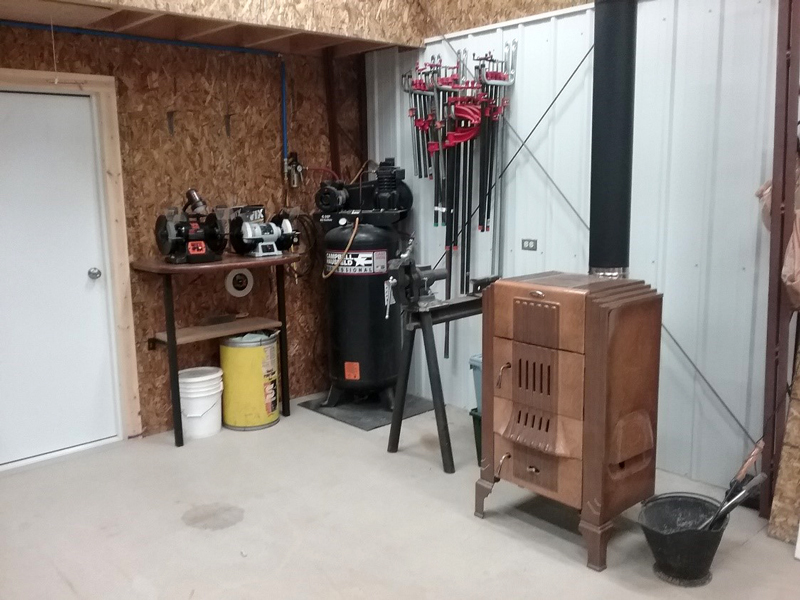

“My wife and I have had a great time building our shop. I am attaching a few pictures of the shop (as you can see, we still have some inside work to do). We have done all of the work ourselves, except for the cement footings and floor. Not too bad for a couple of senior citizens!

Thank you for all your support and encouragement. If anybody would like to see one of your buildings, we would be glad to show them ours.”Russ & Ranae L.

Monroe, UT

Click below to see and read more.

(more…)

Thank you, Russ and Ranae, for sharing your story, and for choosing Worldwide Steel Buildings for your project. Please let us know if we can be of assistance at any time. Enjoy your new shop!

How are you using YOUR Worldwide Steel Building? Let us know – we’d love to hear from you!

Beat the Heat: AC Units for Metal Building

Choosing the right air conditioning (AC) unit for a metal building is a critical decision for year-round comfort and efficiency. Metal buildings, known for their durability and versatility, have unique climate control needs due to their construction material. While the hot summer months might prompt the immediate need for cooling solutions, it’s essential to consider the broader picture. The changing seasons bring varying temperature extremes, from scorching summer heat to chilly winter days.

This necessity for a versatile climate control solution is especially relevant for steel buildings, where internal temperatures can fluctuate due to external weather conditions. Modern metal building kits offer the flexibility to customize HVAC systems to meet these diverse demands. A robust system that not only cools in the summer but also provides warmth during the colder months is vital.

In this blog post, we’ll dive into the factors to consider when selecting an air conditioning unit for your metal structure. Whether it’s a sweltering summer day or a brisk winter evening, ensuring your metal building is equipped with the right HVAC system is key to maintaining a comfortable and energy-efficient environment year-round. Let’s explore how to achieve this balance, ensuring your space is a comfortable haven in any season.

Flexibility to Incorporate Building Systems

Whether you want to air condition the office space within a hybrid warehouse/office structure, or provide climate control for your entire garage, workshop, or single-family steel home, you can plan and lay out your own HVAC (as well as power and other systems) for part or all of your building kit. Need a little help determining what your building needs? Our experienced customer service team can work with you to understand your HVAC and systems needs and customize your building kit to achieve them, with maximum energy efficiency in mind.

Design Elements to Help You Keep Your Cool

While a central HVAC heating system and cooling system is the primary means of keeping things cool in the warm weather (and vice versa), some of the most basic design elements can also be used to help manage climate and air circulation in your steel building:

- Doorways/openings: With clear span buildings 24-225 feet, our steel building kits allow for large garage door openings on multiple sides of the building to provide cross-ventilation. This is most often a consideration when designing the exterior walls of commercial buildings.

- Windows: Another obvious, but important element: Worldwide Steel Buildings’ clear span designs also allow you to place windows to maximize (or minimize) natural light and ventilation based on your specific building site. Homeowners in particular should consider the climate aspects of their prefab steel building kits. When the weather is pleasant, don’t underestimate the power of opening those windows to circulate some fresh air!

- Ceilings/roofs: The open design of our building kits means you can customize the ceiling height and roof pitch to allow heat to rise to the top of your building, vent out of your building and away from your belongings, equipment – and from you. Our building kits also allow ductwork to distribute warm and cool air throughout every square foot of your building.

- Insulation: While much of the energy-efficient climate control is inherent to the properties and design of your steel building, insulation systems make a major impact, too. Whether you opt for loose-fill, blown-in, batt and roll, reflective insulation, radiant barriers or spray foam, your building can accommodate it.

Factors to Consider When Choosing an AC Unit

Insulation and Sealing Requirements for Metal Buildings

Your metal building needs proper insulation to maintain a comfortable temperature. Insulation is measured in R-value; the higher the R-value, the better the insulation. Also, sealing any gaps, especially around garage doors and eaves, is crucial to prevent hot air from entering and cold air from escaping.

Sizing and Capacity Considerations

Selecting the right size AC unit, measured in BTUs (British Thermal Units), is vital for your steel building. An oversized unit can cause humidity issues, while an undersized one will struggle to cool the space efficiently. Consider the square feet of your metal structure when determining the right size.

Energy Efficiency Requirements

Energy efficiency not only reduces energy bills but also lessens the environmental impact. Look for AC units with a high SEER (Seasonal Energy Efficiency Ratio) rating. The higher the SEER rating, the more energy-efficient the unit is.

Environmental Considerations

Consider the climate of your location. In hot areas like Texas and Florida, a more robust system may be necessary. Conversely, in cooler climates, a less powerful unit might suffice.

Installation and Maintenance Tips

Guidelines for Installation

Proper installation is crucial. For DIY enthusiasts, installing a window unit or mini split may be feasible. However, for more complex systems like a split system or heat pump, professional installation is recommended, especially for commercial buildings.

Maintenance Tips

Regular maintenance, like cleaning filters and checking for leaks, ensures optimal performance and longevity. In metal garages, ensure adequate airflow to prevent warm air buildup.

Stay Comfortable in a Worldwide Steel Building

Selecting the right AC unit for your metal building involves considering factors like insulation, size, energy efficiency, and environmental factors. Whether it’s a mini split for your shop or a full HVAC system for a large steel building kit, understanding your building’s needs is key. Remember to factor in ongoing maintenance to keep your air conditioning system running smoothly, and consider adding supplementary elements like ceiling fans and awnings for additional climate control. With the right approach, you can enjoy a comfortable, energy-efficient space in your metal building.

For more information about the benefits of Worldwide Steel metal building kits, contact us today. You can also start designing your building with our online 3D Building Designer Tool!

Customer Success Spotlight: Wings of Faith Ministries

Our goal at Worldwide Steel Buildings is to provide our customers high-quality, affordable steel building kits customized to their unique needs or purpose. We love to share our customers’ stories and the great things they are doing with our products:

Wings of Faith: “Real People Meeting Real Needs”

Wings of Faith Ministries provides ongoing support and donations to missionaries serving mainly Native American populations in California, Nevada, Arizona, New Mexico, as well as communities in Appalachian West Virginia. Their volunteer light aircraft pilots make more than 60 flights a year to bring food, clothing, medical supplies, and other aid to those who need it.

Several years ago, Wings of Faith purchased one of our steel building kits to house supplies and donations awaiting distribution to the communities they serve. Jim Yost, who coordinates logistics and deliveries for Wings of Faith, shared these thoughts and photos:

“Our building from Worldwide has proved absolutely invaluable in serving the very poor of the Native American reservations of the Four Corners area. I cannot imagine doing what we do without it. In May 2018, we moved over 50,000 pounds of supplies through this building.”

Thanks to Jim for sharing your story, and for the great work your organization is doing to help others! To learn more about Wings of Faith, visit flywithwings.org.

How are you using YOUR Worldwide Steel Building? Let us know – we’d love to hear from you!

How Do You Build a Steel Garage 900 Miles from Civilization?

At Worldwide Steel Buildings, we are proud of our processes that make building a steel structure of any kind, anywhere, as painless and streamlined as possible. However, for one of our customers, timing, communication and follow through were of utmost importance. Here is his experience in his words:

A Challenging Location to Build a Steel Building

For most people, any undertaking of a construction project requires major consideration with regard to time money and frustration. Most would prefer to leave these challenges up to a general contractor and in the end, enjoy all the rewards and just write the check.

Our situation in Juneau has additional considerations. First, we live in a remote community 900 miles away from major shipping ports and access is by boat or plane only. Along with our geographical location, we live in a rainforest that receives approx. 120 inches of rain yearly and annual snowfall that can reach 200 inches. All of this provides for approximately 5 months of sensible building time in a calendar year, so a commitment to a timeline and follow through is essential.

Expectations Were Set Low Due to Previous Experiences

Having lived here for 30-plus years has demonstrated that even the best of companies and corporations from the lower forty eight have and are unable to overcome the many challenges that Juneau presents. And for them to oversell and under execute is more often the norm rather than the exception.

All that said, to maintain control of all factors, I decided to be my own general contractor, designer and banker. And with the help from my lovely assistant and wife Pamela, would construct and build our new garage. I knew what I wanted, where I wanted it and how much I could spend.

(Our 3D Building Designer tool helps you get started on the design of your steel building project!)

Worldwide Steel Was Great from the First Contact

After a year of research and planning, I sent out emails to over a dozen steel building providers. This email contained what I would consider a comprehensive list of details and overview of my project. For comparison’s sake, I was patient and waited for many to respond. Perhaps comparison is the wrong term, for it was more of a contrast as replies came in.

Right from the start, Worldwide steel and more specifically, Mr. John Turner, immediately responded, providing information, answering questions, going over options and discussing details. The information Mr. Turner provided seemed to be more confirmed, confident and backed by firsthand knowledge and industry experience than did others who replied.

Communication Was Convenient

In short order, I knew exactly who he was, what he did and how he could help me with our project. Although there was a three hour time difference, Mr. Turner gave me multiple points of contact: email, phone numbers, etc., and I was encouraged to reach out at any time, after hours and on weekends. Other companies literally took months to return any reply, or deferred me to someone else, or someone would have someone else call me back, or sent me to an automated voicemail tree.

The Construction Process Was Seamless

After deciding to go with Worldwide Steel, John and the team at Worldwide put together a seamless chain of events and efforts from architects, engineers, logistics, shipping departments, finalizing plan details and setting up time schedules, as well as providing necessary plans, documentation, and certifications needed for the local permitting process.

At Worldwide I had one contact, John Turner with a direct line, who always answered the phone or called me back within minutes. But more importantly, John was always in line and up to date with the specifics of my project and its progress. I never felt as if my little garage got lost in the day-to-day shuffle of people being too busy to take the time.

My Steel Garage Is On Schedule and Under Budget

As a result of John and the many others at Worldwide, my little garage has become a reality. We are currently on schedule and under budget working on interior and final details. We are able to look back on this project and experience in a positive light (the wife and I are still talking to each other).

If an honest and truthful recommendation based on deeds, performance and proven abilities was ever deserved, well, my hat’s off to Mr. John Turner and the team from Worldwide Steel. Good job!

See more steel buildings our customers have built on our testimonials page.

If you have a steel building in your future, trust the experienced team at Worldwide Steel Buildings. Call us at (800) 825-0316.

How To Use a Steel Building Kit To Build a Pool House

Are you a homeowner dreaming of enhancing your poolside experience? Imagine having a custom-built pool house that not only serves as a storage space for pool toys but also as a stylish extension of your home, complete with a living room or lounge area. Worldwide Steel Buildings offers a unique solution: steel building kits that can be transformed into a fabulous pool house. Our clients, like Rob H., have shared their success stories in creating pool houses that stand out both in durability and design, offering a significant reduction in pool house cost compared to traditional construction methods.

Real Life Customer Shares Their Experience

At Worldwide Steel Buildings, we’re always amazed at the uses our customers come up with for our outstanding buildings. Check out this steel building kit that makes swimming a year-round activity. Rob H. shares how the steel structure not only houses pool equipment but also features a cozy lounge area:

“The steel structure is incredibly strong and stable. We can get up to 1.5 feet of snow in our area and the frame can easily handle that weight load. We also can get high winds here and the structure hasn’t budged an inch. It is also very unique in appearance: the frame inside of the pool space has a geometric look that blends well with the rounded style of our pool. Externally, the frame has a clean look and gives very nice ‘curb appeal’. The steel frame design itself makes it very easy to safely mount any kind of accoutrements we’d like in the space (lights, wireless speakers, things like that). This structure, combined with the polycarbonate siding we chose, gives us a pool space we can use all year. We can cool the building with our fan system during the summer and warm it with area heating in the winter.”

“We couldn’t be happier with how the project turned out. We have a pool house we can use anytime, any season, and this is something that really adds value to the investment we made for our pool space. We can’t wait to do some swimming when it’s snowing outside! Again, thanks for all of your help with this, it took quite the effort but really turned out sensational! Thanks, Rob H.”

Robust and Adaptable Steel Structures for Your Pool House

Steel building kits from Worldwide Steel Buildings are renowned for their strength and stability. Rob H.’s experience highlights this, as his pool house design effortlessly withstands up to 1.5 feet of snow and endures high winds without compromise. The geometric frame not only provides a strong foundation but also adds a unique aesthetic that complements the rounded contours of a swimming pool. This blend of functionality and design makes our steel structures an ideal choice for your new pool house project, seamlessly integrating with your main house and enhancing the overall aesthetic of your property.

Customization Options for Your Dream Pool House

Tailor your pool house to your exact needs with our wide array of customization options. Imagine a pool house with glass doors opening to the backyard pool, or a custom build with a built-in bar and ample space for outdoor furniture. Our kits enable you to create a pool house that’s not just an add-on but a significant enhancement to your outdoor living space, offering a variety of pool house features to suit your lifestyle, whether it’s a simple changing room for swimmers or a fully equipped living space.

All-Season Enjoyment in Your Custom Pool House

Our customer Rob H. also showcased how the addition of polycarbonate siding to his pool house facilitates year-round usage. This adaptability means you can enjoy your pool area in all seasons, whether it’s cooling down in the summer with a fan system or staying warm in the winter with area heating. A Worldwide Steel pool house offers homeowners like you the opportunity to swim even when it’s snowing outside, transforming your pool area into an all-encompassing recreational space.

The Cost-Effective, DIY-Friendly Pool House Solution

Building a pool house with our steel kits is not only a cost-effective solution but also a DIY-friendly project. This approach allows you to design and build a pool house that meets your specific needs, from landscaping integration to incorporating a prefab pool house structure. The result is a personalized, custom pool house that enhances your swimming pool area and adds significant value to your property.

Navigate Zoning and Pool House Construction with Ease

Embarking on pool house construction requires understanding local zoning laws. Worldwide Steel Buildings provides the expertise to navigate these regulations, ensuring your pool house meets all requirements. Our steel kits offer the flexibility to create a variety of pool house ideas, from a simple poolside shed to an elaborate, custom-built structure, perfect for any type of pool house you envision.

Start Building Your Ideal Pool House Today

Ready to dive into your pool house project? Worldwide Steel Buildings is here to assist you every step of the way. To explore more about our metal building kits and how they can be used to build a pool house, visit our testimonials page. For further information and to start planning your dream pool house, call us at (800) 825-0316 or download our building planning kit. Embrace the opportunity to create a unique, durable, and stylish pool house that you and your family will enjoy for years to come!