Steel Frame Building

Bringing You the Best Design in Rigid Frame Steel Buildings

Steel frame buildings are an excellent alternative to traditional wood-based construction. Steel building kits not only provide incomparable durability and longevity, but require much less maintenance, offer unmatched energy efficiency, are fully customizable to your needs and are cost-effective at the time of the build as well as over the life of the building. Plus, steel frame construction time is much shorter than the time required to erect a traditional build.

If you’re looking for a steel structure fast, choose one with an industry-leading warranty and unbelievable customization options. Choose one of the steel building kits from Worldwide Steel.

Worldwide Steel Buildings is a leading supplier and manufacturer of prefab rigid frame steel buildings. We are dedicated to bringing our customers the best value in their steel building needs. Our rigid frame steel buildings are created for multiple uses from manufacturing, warehousing, retail, residential, mini storage, churches, and many other commercial and agricultural uses. We also offer some of the fastest turn-around times in the industry, providing you with stamped engineered drawings in a couple weeks and delivery of most building kits to your job site in just 6-8 weeks.

Our team of experts will help you from concept to delivery. Curious about what kind of door spacing you need for your building, which clear span would be ideal, what the building codes and snow loads are in your area? Our experts know!

We’ve designed our steel frame buildings to be truly DIY. Even if you have no previous construction experience, you’ll find the Worldwide Steel construction process simple and straightforward.

When you need the steel framing of your new building to be manufactured right, you can depend on Worldwide Steel Buildings. Take a look at what some of our customers have done with Worldwide Steel building kits:

Recent Rigid Frame Steel Building Projects

Rigid Frame Steel Building Technical Information

Worldwide Steel rigid frame steel building systems are manufactured in AISC- MB and ISO 14001:2004 certified facilities. We are dedicated to protecting our environment and reducing waste. In order to be awarded an ISO 14001 certification, our facilities underwent a rigorous auditing process by an accredited firm. This demanding process takes about a year to achieve, but is an extremely worthwhile investment to ensure our commitment to proper waste management and environmental protection.

An increasing emphasis on sustainability in the construction industry will involve the energy conservation and environmental impacts of construction. That’s why we prioritize our ability to design and produce energy-efficient buildings. In addition to these certifications, we prioritize sustainability by using all U.S. recycled steel in every Worldwide Steel Building.

All of our buildings are designed using MBA software to meet your specific codes. Our design and detailing processes are audited to ensure your requested codes are being met in a rational engineering manner and that all proper design standards are being applied.

What Does That Mean to Our Customers?

MBS Software

- Buildings will be created to meet your specific codes

- Buildings are optimized to build a quality building at the best possible price

AISC-MB Manufacturing Facility

- Most comprehensive quality certification program of its kind

- Detailing processes are audited to ensure requested codes are being met and that all proper standards are being applied

- Raw materials are audited, including use of proper standards, tracking of mill certifications, etc.

- Manufacturing process is audited, including machinery calibrations, measuring tools, welding certifications, etc.

- All audits are performed on-site by third parties

Steel Frame Building Colors

We have a wide variety of colors to choose from for your rigid frame steel buildings.

Steel Frame Building Sizes

Complete metal building packages can be customized and combined with other materials to create an aesthetically sound building for your special requirements. Worldwide Steel Buildings offers a wide array of structural systems including clearspan rigid frame, modular rigid frame, tapered beam, and lean-to. All are available in standard or long bay options. Your building can be produced to virtually any desired dimension to achieve the optimal solution for your building requirements. All buildings are in accordance with the MBMA Metal Building Systems Manual and adhere to your specified buildings code.

Worldwide Steel Buildings also offers open web truss building packages in widths of 12′ through 100′ clearspan with side wall heights 8′ through 20′. Other sizes and heights available upon request.

Steel Frame Building Erection Manuals

We created our steel frame buildings with the do-it-yourselfer in mind. All Worldwide Steel Building trusses are pre-punched, easily bolt together, and have the purlin and girt clips factory welded for the easiest construction method. All steel purlins and girts attach to the clips with self-drilling screws. Your sheet metal attaches to the purlins and girts with colored, self-drilling screws that are flanged and self-sealing to prevent leaks, making frame construction and finish easy. Your steel structure kit also comes with a step-by-step erection manual to guide you or your local contractor from the start of your steel framing through the completion of your building.

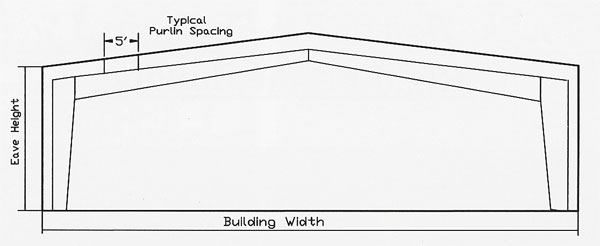

These tapered framing members are typically used in clearspan situations from 40 ft. to 150 ft. It can be either gable or single slope. Common roof slopes of 1 in 4 to 4 in 12 are offered. When large clearspan areas are required for special industrial and commercial projects, the clearspan frame is typically the economical choice. The clearspan can be used with either cold-formed purlins or open web joists.

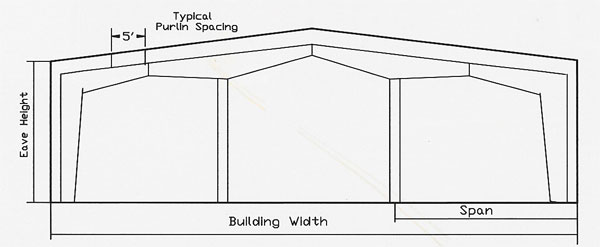

The solid web rigid frame with interior columns provides multiple spans on wider buildings. It can be either gable or single slope. This frame type is economical with individual spans of 40 feet to 80 feet and building widths from 80 feet to 300 feet plus. Roof Slopes are 1 in 4 to 1 in 12.

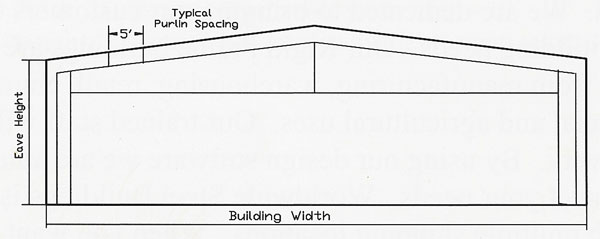

The straight column rigid frame is ideal for maximum efficiency of interior space. It is suitable for all types of small buildings that require clearspans from 20 feet to 60 feet. Roof slopes of 1 in 4 to 1 in 12 are available. The Tapered Beam frame is ideal for partitioning interior bays and small crane support systems.

Standard Rigid Frame Steel Building Features

Primary Framing

Solid I-Beam Construction for Optimum Strength of Your Building

Our designs use the highest yield strength material, allowing for a smaller web which not only provides a space-saving design, but a greater cost savings to our customers. Laser cut, pre-punched and sub-arc welded to ensure the highest precision.

End Wall Frames and Columns

Your end wall frames and columns are based on your specific building design requirements using either cold formed, mill-rolled or built up I sections to ensure it provides the greatest functionality.

Secondary Framing

Girts

8” or 10” based on design requirements. Cold rolled Z-section, 13 gauge to 16 gauge ASTM A- 570, 50,000 or 65,000 psi yield material used to provide maximum strength. By-Pass girt system over laps at sidewall columns forming a continuous connection for extra strength.

Purlins

8”, 10”, 12” based on design requirements. Top mounted to your roof girders with a varied lap of 2’ to 6’ for strength and cost savings in the erection labor. Maximum purlin spacing is 5’ on center. Purlins also use the By-Pass system for maximum strength.

Eave Strut

Cold formed C-Section that is rolled for the appropriate roof pitch to help insure all Worldwide buildings are weather tight at the eave.

Sheeting Angle

A continuous angle supplied with every Worldwide building for the attachment of the sheeting at the rake of the building for ease installation of your sheeting and ensuring a weather tight seal along the gabled eave.

Base Angle/Girt with Trim

A continuous angle or girt supplied with every Worldwide building for the attachment of your sheeting to the concrete. This is easily attached with ram-sets or equivalent anchors by others and ensures a weather-tight seal along the base of your Worldwide building.

Bracing

Every Worldwide building comes supplied with bracing in your walls and roof to prevent longitudinal loads and truss racking. This is accomplished by diagonal rod, cable, wind columns or portal frames based on your design needs.

Angle Flange Bracing

Provided with every Worldwide building to connect your rigid frames to the Purlins and Girts. This ensures that allowable compression levels are adequate for any combination of loadings.

Purlin bridging angles may be provided at each mid-bay to assure consistent purlin spacing and stiffening.

Structural Bolts

Structural bolts used with Worldwide buildings meet requirements of ASTM standards. ASTM Standards require A-325 for primary frame connections and A-307 for secondary framing.

Self Drilling and Self Tapping Fasteners

Pre-assembled with neoprene washers and domed metal caps to help ensure weather tightness of your steel building. This prevents leakage and prevents potential water damage. One of many features that sets a steel building apart from traditional construction.

Sheeting

80,000 psi

80,000 psi yield material is the standard on all Worldwide Steel buildings. Some manufacturers use a lower yield strength material, which is less resistant to damage from hail and other impacts.

All Coil Steel

All coil steel with Galvalume coating standard (1.25 oz – hot dipped) on each side helps prevent deterioration of the steel sheeting.

Deeper High Rib

Deeper High Rib with more frequent corrugation provides superior strength for the steel building.

Purlin Bearing Rib

The purlin bearing rib provides a better weather seal between the roof sheets on your steel building.

Optimal Semi-Concealed Panel

This configuration is available for walls, facade systems, soffit material, etc. to add an aesthetic appeal to your Worldwide Steel building.

Sealants/Trim/Flashing

Sealants

For roof side laps, end laps, and flashing gable is provided to help ensure weather tightness. Nominal 3/8” x 1/8” thick pressure sensitive tape sealant for ease of installation.

Trimming & Flashing

Trimming at rake (gable) corners and eaves is provided for all Worldwide Steel buildings with standard trim material for a finished look. This is also a moisture deterrent and helps prevent insects and dirt from getting into the building.

Ridge Cap

Pre-formed High Rib Ridge Cap Panel

Matches the slope and profile of the adjoining roof panels on Worldwide buildings to help ensure constant alignment and weather tightness.

Long Overlap

Provided to help prevent water from siphoning into the building.

Plans & Drawings

Anchor Bolt Setting Plan

Demonstrates building reactions for all buildings. Details where your column locations are for an exact location of your anchor bolts.

Engineer Certified Erection Drawings

Including wall and roof framing diagrams, cross sections, sheeting and flashing details are provided. These drawings show clearly the proper erection and assembly of all building components

Worldwide Building Manual

Erection drawings provide step-by-step instruction for assembly of your building

Part Numbers

Placed on each component (other than bolts and fasteners) These part numbers coincide with a detailed listing contained in the construction drawings and shipping list to help with assembly of the building.