Metal Building Trim

A Worldwide Steel building is supported almost entirely by its strong, durable stainless steel truss and fastener system. That means no matter what you use for siding and trim on your metal building, the strength comes from what’s inside. However, the roofing and siding you choose are important as well. They keep what’s inside your building protected, keep the elements and pests out, and handle snow and wind loads.

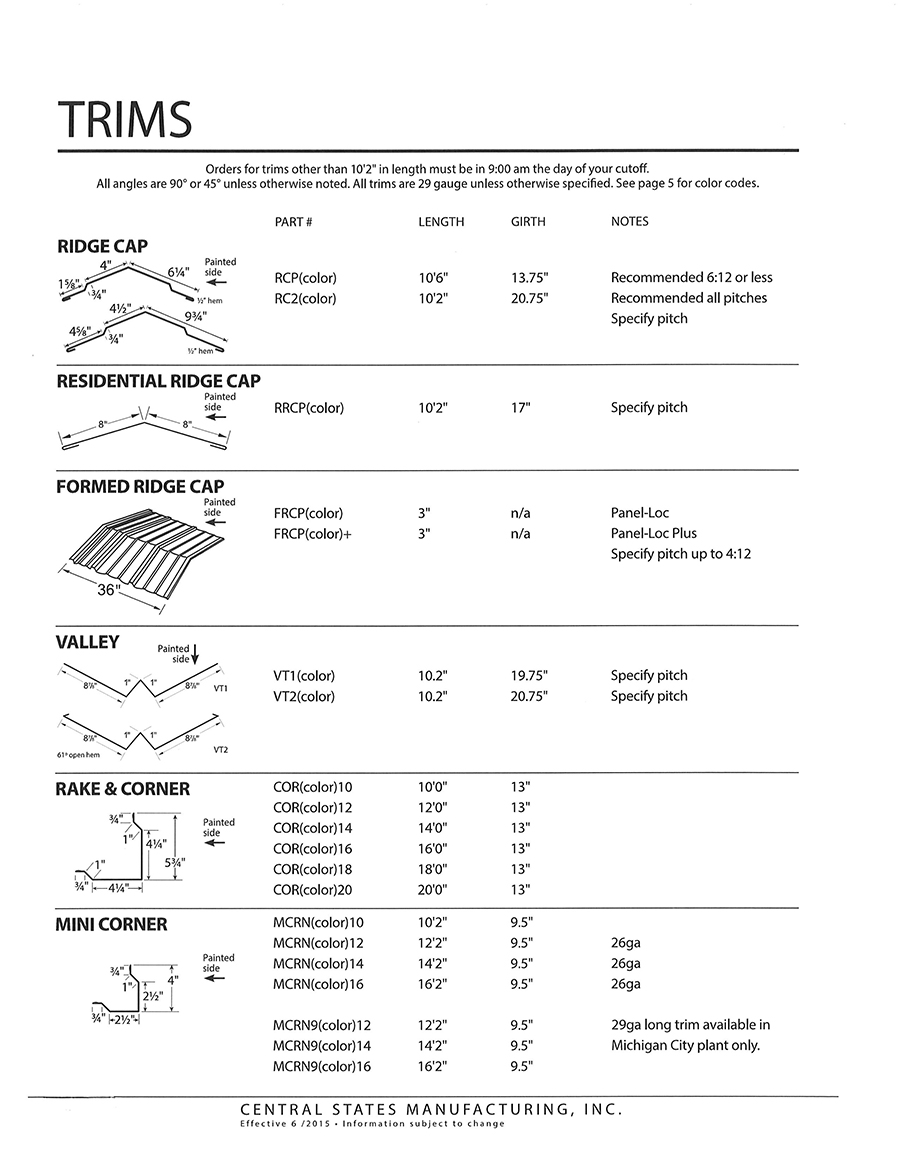

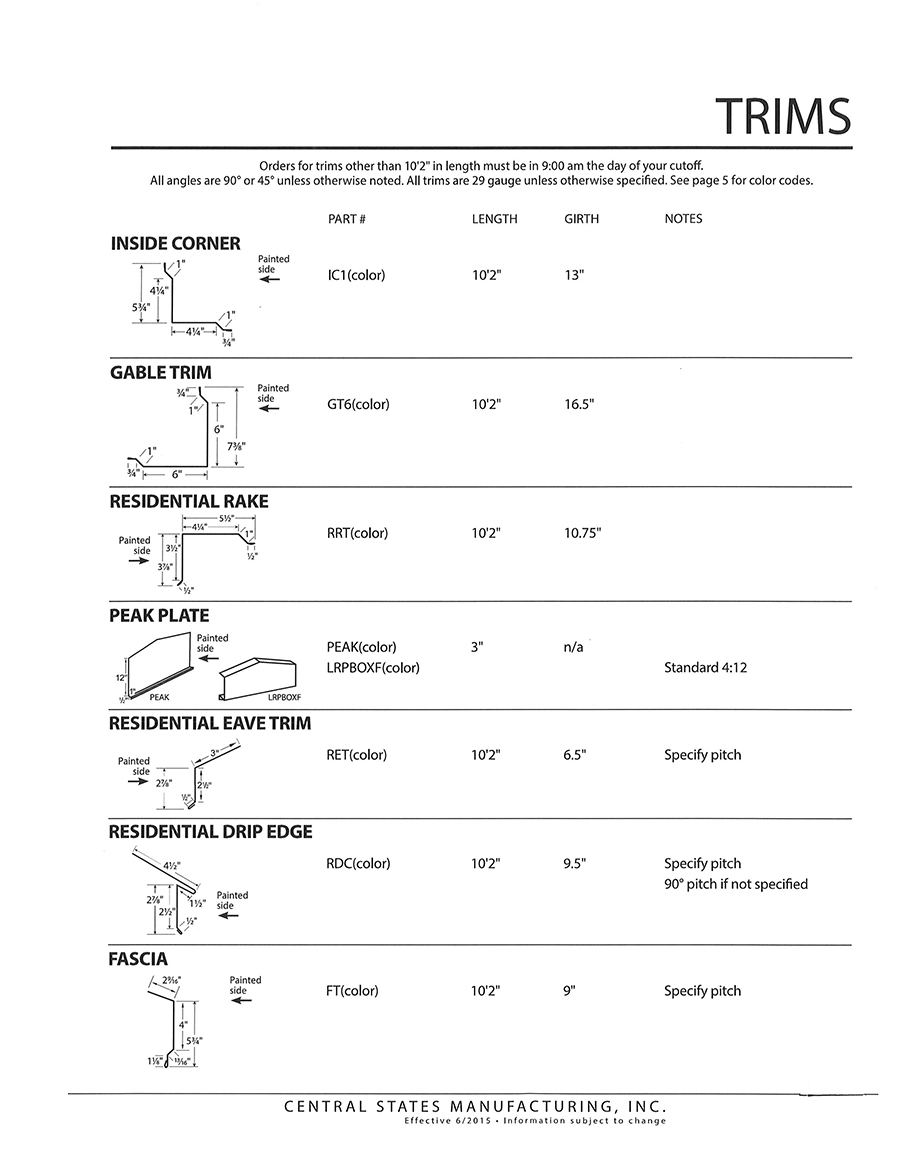

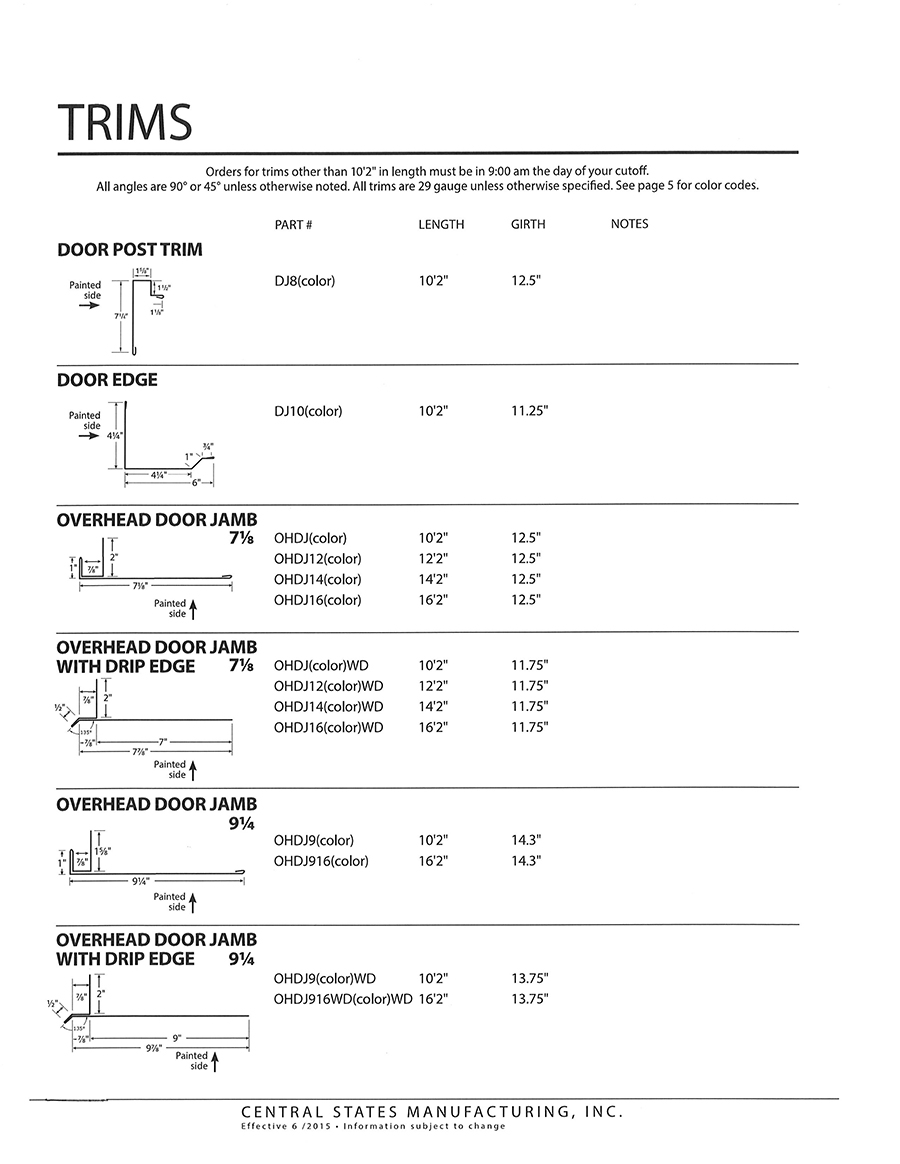

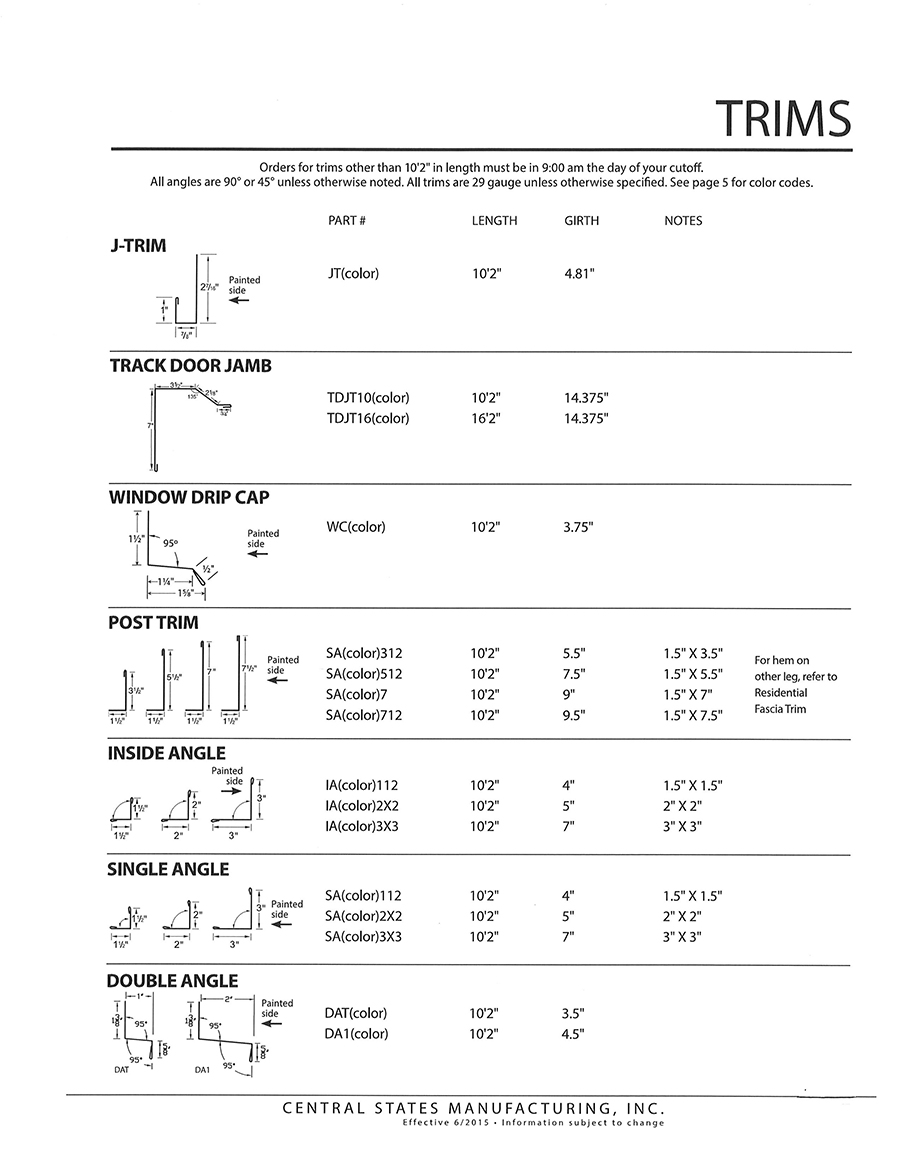

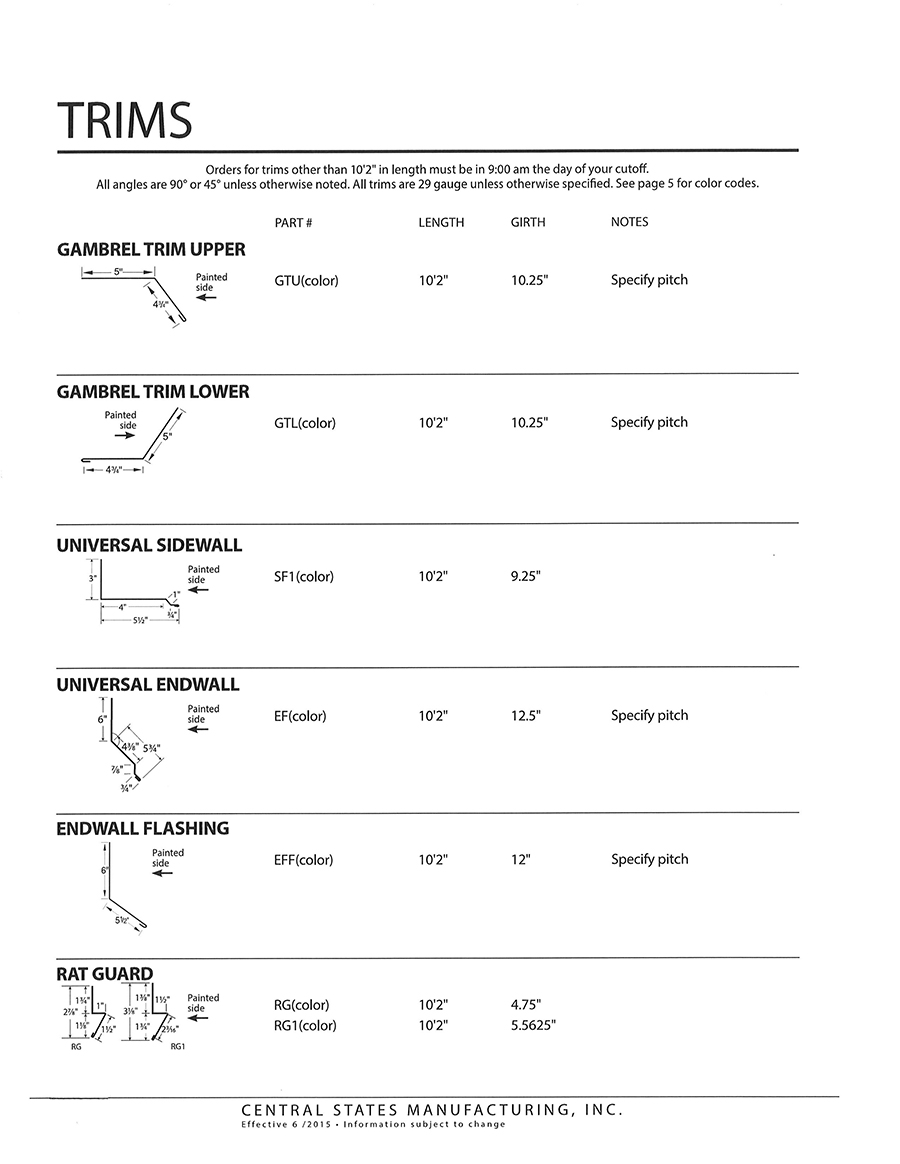

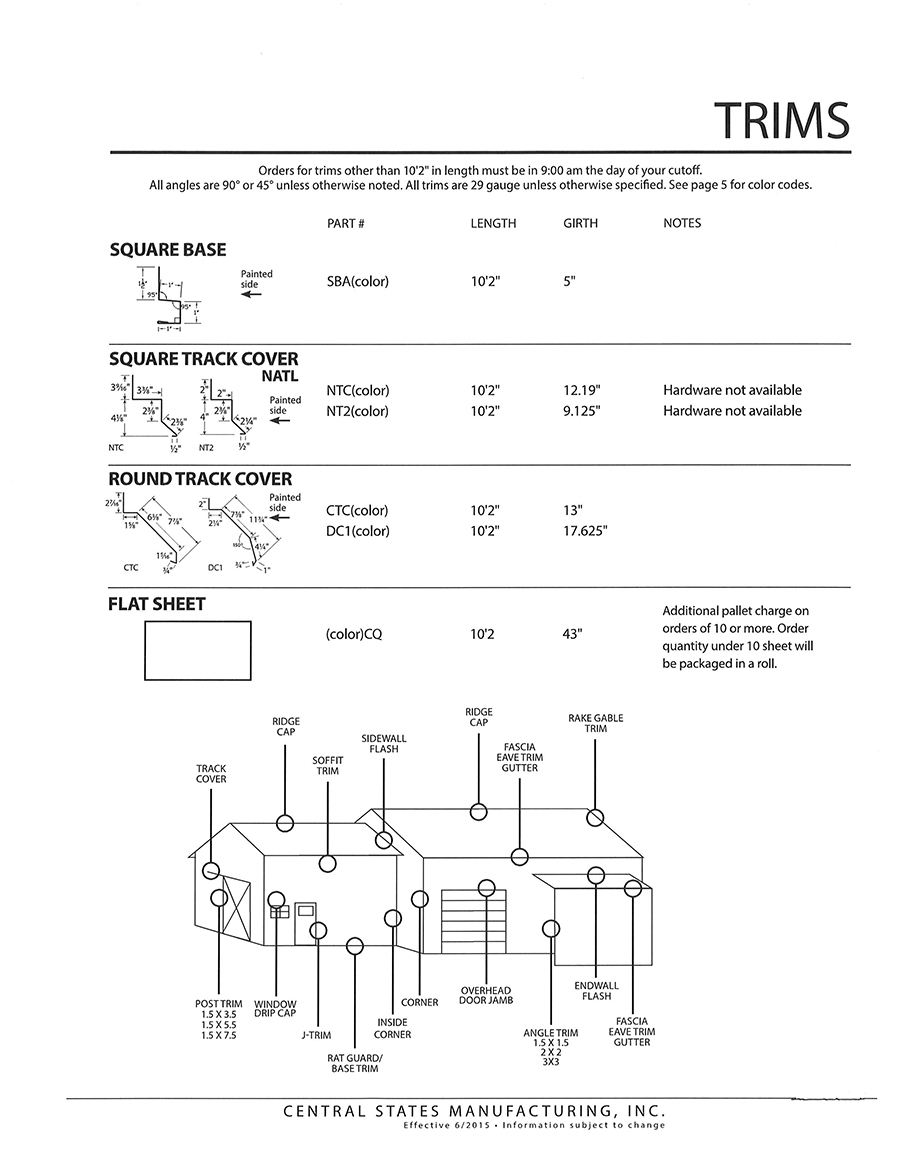

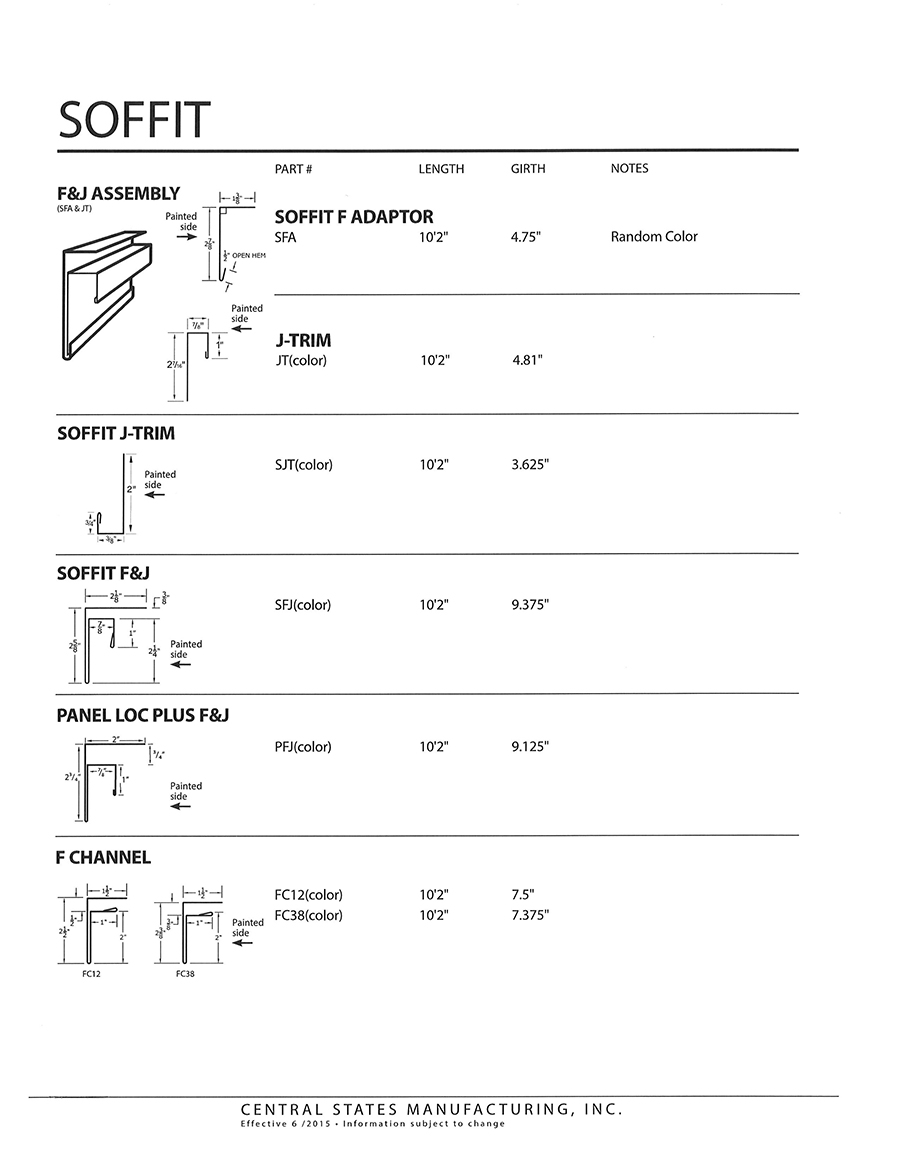

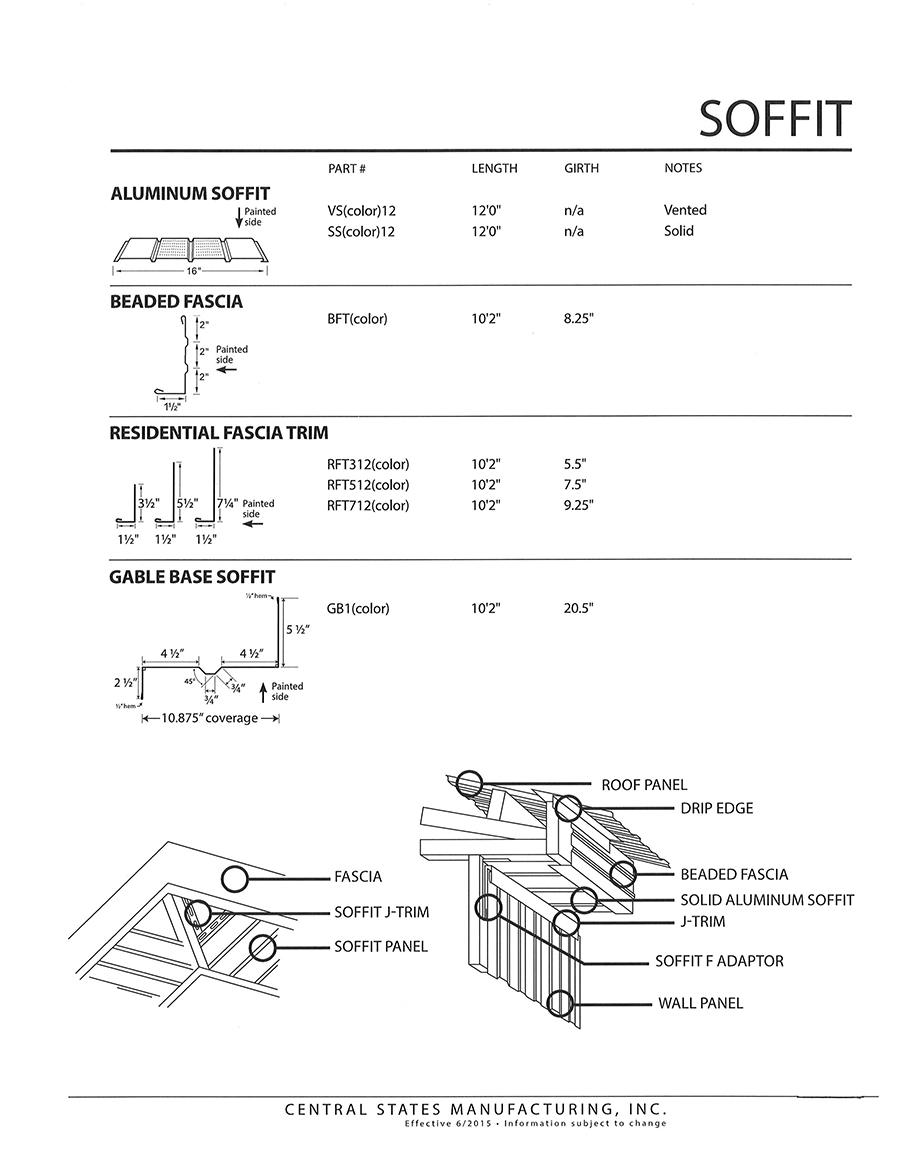

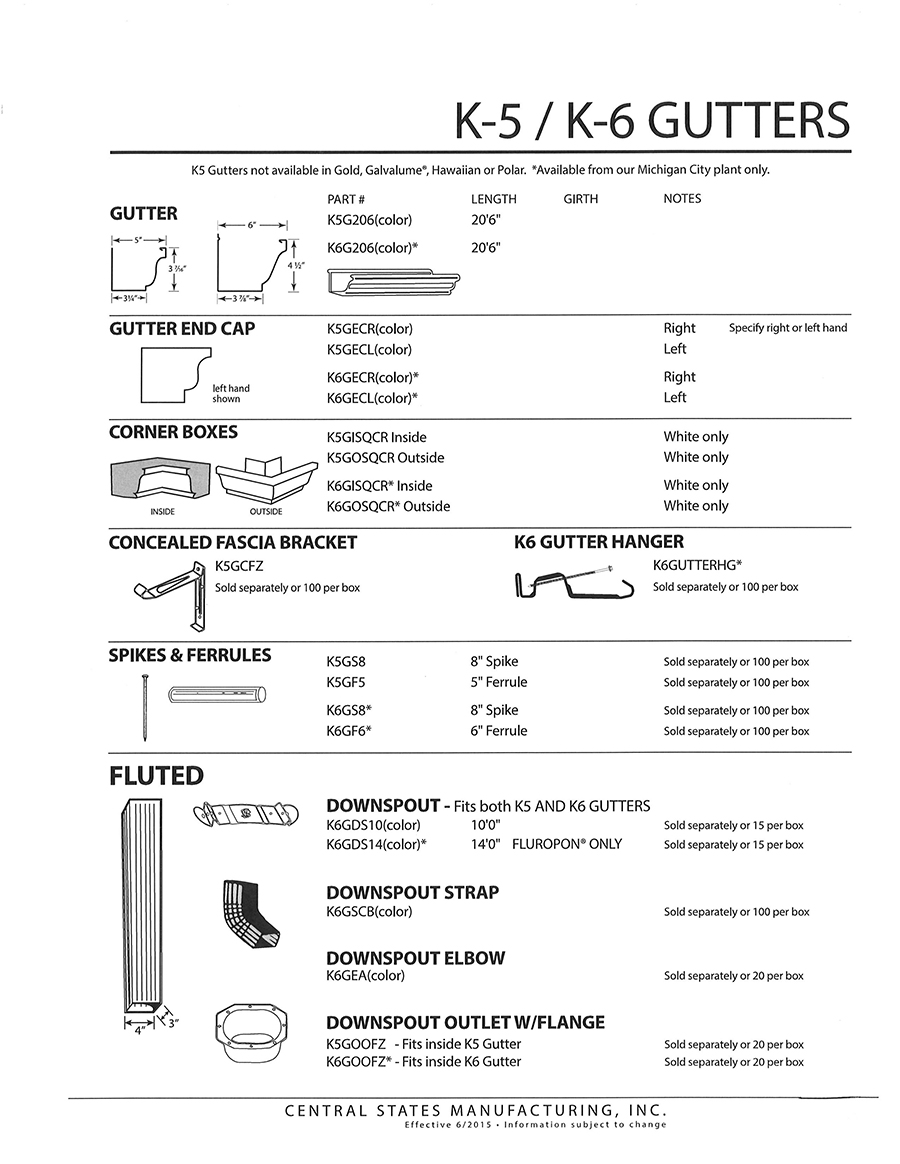

When it comes to siding your metal roofing and building, stainless steel sheet metal is a popular choice among our customers. At Worldwide Steel Buildings, we proudly offer top-tier sheet metal wall panels, metal roof panels, and an array of custom trim products, such as corner trim, eave trim, and base trim. We also offer soffit, gutters and downspouts, and much more!

Our commitment to customization ensures that even as you incorporate these building supplies into your metal building kit, you can achieve the look you’re going for with your building project.

Plus, every building system Worldwide Steel fabricates, whether it’s a shop, garage, storage shed, hangar, or home, comes with an industry-leading 50-year warranty. When you include sheet metal and trim as part of your building kit, that too comes with a 40-year warranty. Because Worldwide Steel is the manufacturer of our products, including all metal fabrications, we stand behind what we sell. All together, that equals the most installer-friendly, maintenance free metal building you can own.

Sheet Metal Trim and Panels

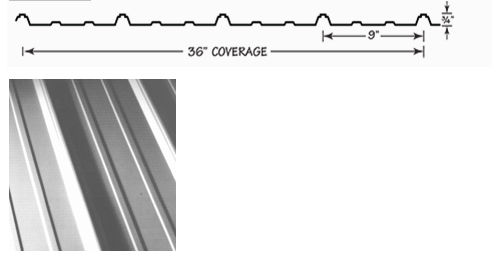

Panel-Loc Plus™

Panel-Loc Plus™ is a low rib (3/4”) panel which provides durable performance with an added striation on top of the rib that gives it even more strength. Panel-Loc Plus™ gives agricultural and light commercial projects, as well as residential roofs, the protection of steel with an attractive appearance. It is available in 26 and 29 gauge steel, as well as aluminum.

General Information

- Panel rib height: 3/4″

- Panel coverage: 36″ wide

- Panel length: 26″ to 45′ in .5″ increments

- Tensile strength: 80,000 psi minimum

- Substrate: varies by option; Galvalume® (AZ-50) or galvanized (G90)

- Gauge: 26 and 29

- Recommended roof slope: 3:12 pitch minimum or greater

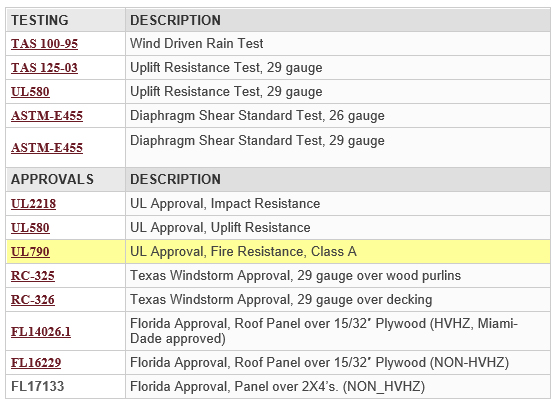

Testing and Approvals

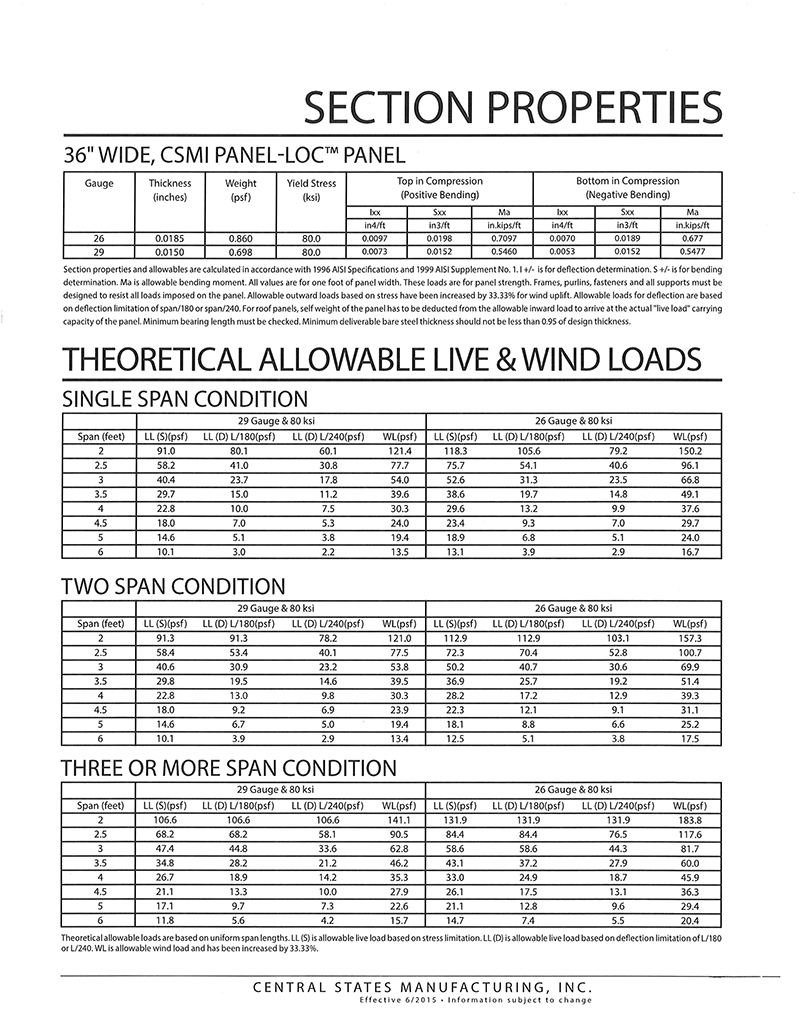

Our trim piece products have been rigorously tested to make sure that they meet the highest standards of quality. We seek to meet or exceed the industry standards by focusing on our 520 quality control checks to ensure a consistent, reliable product. The chart below summarized the testing and approvals that are available on each product. In some cases, products are licensed, and testing will be available in the licensor’s name.

Coatings

Worldwide Steel Buildings cares deeply about the products we sell and the vendors we work with. When we send our sheet metal out to customers, we want to ensure it meets the same standards as the rest of our steel products. That’s why we work with the best coating and sealant manufacturers, to ensure your sheet metal flashing, siding and roofing are protected from rust, corrosion, pests and the elements.

CentralGuardTM powered by Valspar

CentralGuardTM is the toughest siliconized polyester coating available for sheet metal. It combines the durability of ceramic and select inorganic pigments with the strength of a proprietary silicone polyester resin formula to offer extreme weather, stain and abrasion resistance and minimal chalking and fading. All CentralGuardTM colors carry a 40 year limited warranty.

CentralGuardTM offers a unique blend of the finest components of paint: resin, pigment and solvent. Each of these components, working together, plays a critical role in the performance and application of the paint.

- Resin is a material used to hold pigment particles in suspension and attach them to the painted surface. Chalking is caused when harmful ultraviolet light rays from the sun, as well as acid rain, pollution, salt spray and other weather-borne chemicals degrade the resin system. When a coating chalks, resin particles at the surface lose adhesion and take on a powdery white appearance.

- Pigment is an insoluble, finely ground material that gives paint its color and its ability to hide small irregularities by filling and leveling. Color can fade or change as a result of the effect of elements in the environment such as ultraviolet light.

- Solvent is any liquid that can dissolve a resin and make it fluid enough to apply. After paint is applied the solvent evaporates, leaving the resin and pigment solids on the painted surface where they protect it from the environment and give it an attractive appearance.

Substrates

Galvalume

Galvalume substrates are coated with an alloy of zinc plus aluminum. Galvalume has two to four times the corrosion resistance of Galvanized steel, even in harsh environments. When properly installed, these corrugated Galvalume sheet metal panels will shed rain and eliminate ponding water, which helps reduce corrosion. Central States Manufacturing, Inc. offers a 20-year substrate warranty on all products with a Galvalume substrate.

Galvanized

Galvanized substrates are coated with zinc. Three commonly used Galvanized substrates are G40, G60 and G90. The number values represent the total amount of zinc contained on both sides of the panel surfaces. G90 contains .9 ounces of zinc for every square foot of the panel, G60 contains .6 ounces of zinc per square foot of the panel and G40 contains .4 ounces of zinc per square foot of the panel.

Panel-Loc PLUS™

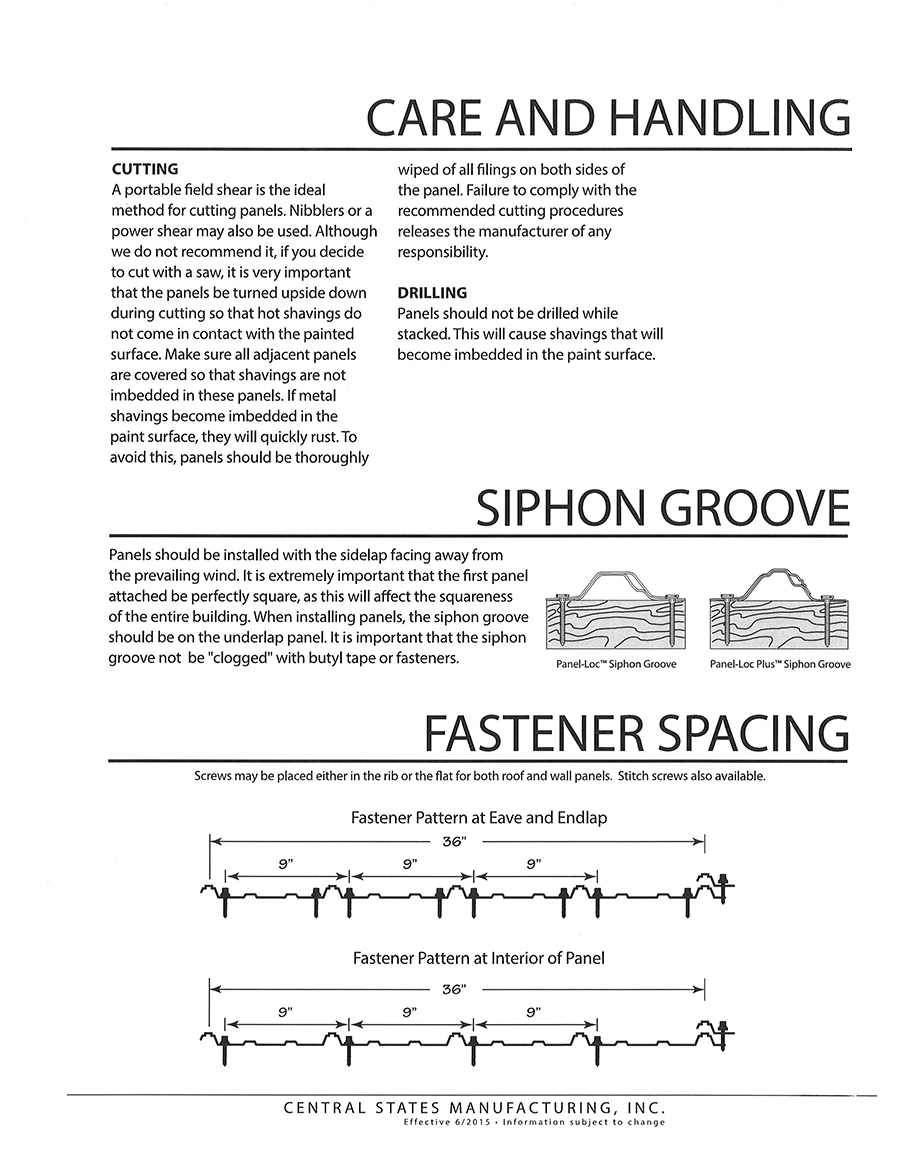

Panel-Loc Plus™ is available in 29ga and 26ga painted Galvalume®, bare galvanized, and bare Galvalume®. Central States uses the CentralGuard® paint system on all Prime painted metals. The paint has a 40 year limited warranty, and Galvalume® substrate has a 20 year limited warranty. Fluropon® 70% PVDF paint system is also available – contact sales rep for details. Bare (non-painted) metals from Central States will have an acrylic coating. This acrylic coating helps protect the metal during manufacturing and installation. This clear organic treatment applied over the Galvalume® and galvanized coating is invisible, but provides enhanced performance applicability and retained heat reflectivity. There is no need for oils to be applied during forming. This organic treatment eliminates fingerprinting and foot marking during installation. Central States’ 29ga and 26ga steel are manufactured to meet ASTM A792 specifications for Galvalume® and ASTM A653 for galvanized with a minimum yield of 80,000 PSI. Panel-Loc Plus also has UL2218/ Class 4 impact resistance rating and UL790 Class A fire resistance. The minimum roof slope for the 3/4″ Panel-Loc Plus™ is 3:12. The minimum pitch, along with Panel-Loc Plus’ siphon groove, will allow for sufficient drainage of water. For added protection, a sealant tape can be used on the laps of the panel.