Galvanic Corrosion Stainless Steel

Often, stainless steel is recommended for buildings that are more likely to corrode, based on how they’re going to be used. But when incompatible metals are used in direct contact with the steel, galvanic corrosion and even pitting corrosion can occur. This corrosion drastically affects the strength and safety of your stainless steel building, so Worldwide Steel goes to great lengths to avoid it.

Hot-Dip Galvanize (HDG) and GALVALUME • Coated Steel Sheets are intended for applications where excellent corrosion resistance is required. The metallic coatings provide an electrochemical barrier and galvanic corrosion protection to the steel.

However, under certain conditions, United States Steel Corporation (U. S. Steel) does not recommend using HDG and GALVALUME • Coated Products or recommends using additional precautions to minimize corrosion and slow corrosion rate. These conditions include:

CONTACT WITH ELEMENTS LESS ACTIVE THAN ZINC OR ALUMINUM

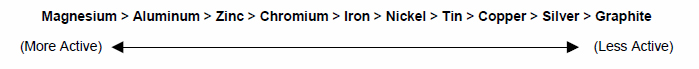

Galvanic corrosion occurs when two dissimilar metals are electrically coupled in the presence of a corrosive electrolyte, one of them is preferentially corroded while the other is protected from corrosion. Any alloy (the anode electrode) will be preferentially corroded when coupled to a less active alloy (the cathode electrode). The relative activities of various metals are ranked in the Galvanic Series of metals for a given corrosive electrolyte, such as seawater (the galvanic current). The relative positions of different metals in the Galvanic Series for seawater are, in order from more to less active:

Magnesium, aluminum, zinc, chromium, iron, nickel, tin, copper, silver and graphite.

The relative positions of the metals may change in different environments. Even so, this is a good guideline for the environments in which HDG and GALVALUME • Coated Products are commonly used. This means HDG and GALVALUME • Coated Products have varying levels of compatibility with different metals, some of which are more likely to corrode than others.

Examples of some materials to avoid placing in direct contact with HDG and GALVALUME • Coated Products include:

- Copper, including copper bearing chemicals from pressure treated lumber, and water drainage from copper pipes such as air conditioning unit

- Iron, including iron debris and saw fines left over from cutting panels, or weld splatter

- Graphite including pencil marks. Coal dust, although not graphite, should not be allowed to accumulate on HDG or GALVALUME • Coated Products.

Lead

TIME OF WETNESS AND CONDITIONS THAT DO NOT ALLOW PROTECTIVE OXIDES TO FORM

Zinc and aluminum form a protective oxide layer when exposed to air, which reduces the corrosion rate of the metal. Conditions that lead to the breakdown of the protective films and adversely affect the corrosion resistance of the HDG or GALVALUME • Coated Products, leading to excess galvanic corrosion, include:

- Harshly corrosive environments such as marine environments increase corrosion potential. Salt water destroys the protective oxide films of aluminum and zinc making them much more chemically active

- Contact with materials that retain moisture including wet insulation, piles of leaves, ash, dust, or other organic debris, etc., which can become wet. Extending the time of wetness should not be left in contact with the coated sheet

- Ponding water or maintaining wet conditions for extended periods of time

- Material kept in tight wraps, bundles or coils and allowed to get wet either by rain or condensation. Under these conditions, air cannot move in to repair the protective oxide films and corrosion can be developed quite rapidly. This is why we recommend our stainless steel building kits are covered loosely if they must be stored at the construction site. It is important that HDG and GALVALUME • Coated Products are not allowed to get wet during storage or at the construction site. More information on storage stains can be found in U. S. Steel Construction Technical Bulletins at http://www.ussconstruction.com

Additionally, the GALVALUME • warranty is voided to bare GALVALUME • roof panels with a pitch less than ¼ :12 (1 degree), because less steep roofing is more susceptible to cathodic activity.

CORROSIVE ENVIRONMENTS

Zinc and aluminum are readily attacked by acids with a pH less than 4, for example:

- Muriatic Acid (hydrochloric acid, HCl) that is contained in some of the cleaning products used to clean brick and concrete, which is very corrosive to HDG and GALVALUME • Coated Products.

- Oil of Vitriol (sulfuric acid, H2SO4), sulfur dioxide (SO2) from chemical plants dissolves in water and forms sulfuric acid. Very strong acid can develop as the water evaporates.

- Similarly, hydrogen sulfide (H2S) in animal confinement buildings can dissolve in water condensate to eventually produce sulfuric acid.

- Nitric acid (HNO3) in fertilizers and also present in animal wastes.

- Zinc and Aluminum can be attacked by alkalis having a pH greater than 9, for example:

- Caustic Soda (Sodium Hydroxide, NaOH).

- Lime and Slaked Lime (CaO and Ca(OH)2 ). For this reason, HDG and GALVALUME • Coated Products should not come in contact with uncured concrete.

- Fly ash from power stations.

- Ammonia (NH3) dissolves in water to form an alkaline solution of ammonium hydroxide (NH4OH).

Worldwide Steel Buildings works hard to ensure as little corrosion potential of your stainless steel building as possible by manufacturing our building kits from corrosion resistant materials and combinations. However, corroding is possible under certain conditions, especially when anodic and cathodic metals (like a carbon steel and a copper alloy or nickel alloy) are in prolonged contact. This is one of the reasons we preassemble so much of our metal building kits before delivering them to you – even using the wrong fasteners or bolts (we use only stainless steel fasteners and steel bolts) on your trusses can cause dissimilar metal corrosion and void your warranty.