Hail Proof Metal Roof

According to a report called U.S. Hail Damage Insights, more than 7.1 million U.S. properties were affected by hail damage in 2019 alone, resulting in losses of more than $13 billion. While most homeowners policies from most insurance companies do cover hail damage, few building owners escape a storm without paying some replacement costs out of pocket.

While hailstorms are most concentrated in the southern and central plains states, they have been observed almost everywhere that thunderstorms take place. Hailstorms can potentially cause damage to any exposed objects, especially when hailstone diameters exceed one inch. The level of hail damage depends on the size, density, falling velocity and distribution of the hailstones, as well as the climate and the building structure.

Because of their surface area and relative lack of obstruction, roofs are very susceptible to hail damage. Hail impact can cause more damage to low slope roofs than to high slope roofs, because the most damage occurs at a 90-degree angle impact. Therefore, a steep slope (6:12 and greater) will improve the impact resistance of a roof. In general, hailstone damage can be categorized into two types: cosmetic damage and functional damage. Cosmetic damage is damage that has an adverse effect on appearance, but does not affect the performance of the roof. Functional damage results in diminished water-shedding ability and a reduction in the expected service life of the roof.

While Worldwide Steel offers an industry-leading 50-year structural warranty on all our steel building kits, that warranty applies primarily to defects in the product and our workmanship. Unfortunately, we are unable to guarantee replacement of roofing systems damaged by hail. That’s why we recommend our customers invest in a hail-resistant roof while designing their metal building, to reduce the likelihood of damage occurring in the first place.

Impact Resistance of Roofing Material

The most effective way to reduce hail damage is to use impact resistant roofing products. Underwriters Laboratory has developed a test, UL 2218, to evaluate the impact resistance of roofing material. This test evaluates materials by dropping a 2-inch steel ball onto the roofing panel twice at the same location, simulating the impact of large hailstones. The material must show no evidence of fracture, cracking, splitting or any other failure, which would result in an opening of the roofing material, to earn the highest rating. Four impact levels are defined in Table I. Class 4 is the most impact resistant, earning the highest rating. Class 1 is the least impact resistant. The Institute for Business & Home Safety (IBHS) has recommended UL2218 Class 3 or 4 products in hail-prone regions 2.

Table I. UL 2218 Class Rating Description 3

| Rating | Diameter of Steel Ball (in.) | Drop Distance (ft.) | Specification |

| Class 1 | 1.25 | 12 | No crack |

| Class 2 | 1.50 | 15 | No crack |

| Class 3 | 1.75 | 17 | No crack |

| Class 4 | 2.00 | 20 | No crack |

There are many different types of materials available for roofing applications, and metal is one of them. While metal roofing is primarily used for commercial applications, it has become an attractive alternative for residential roofing because its relatively lightweight, meets UL2218 Class 3 or 4 specifications, and may have a Class A or B fire resistant rating. Metal roofs have good impact resistance and are very likely to survive hailstones without functional damage, but can be vulnerable to aesthetic damage since hail can cause permanent indentations in the roofing panels.

DENT RESISTANCE OF HOT-DIP GALVANIZED AND GALVALUME • COATED SHEET STEEL

There are many different types of metal roofing solutions, all with different levels of durability against inclimate weather. Although they might have the same UL2218 rating, the dent resistance could be different. Most common metal roof materials are hot-dip galvanized (HDG) or GALVALUME • 4 Coated Sheet Steel, which are either zinc or aluminum-zinc alloy coated steel respectively. The dent resistance of the coated sheet steel is proportional to the square of the yield strength multiplied by the fourth power of the sheet thickness of the steel substrate, and is independent to the metallic coating:

Dent resistance (Yield Strength)2 x (Sheet Thickness)4

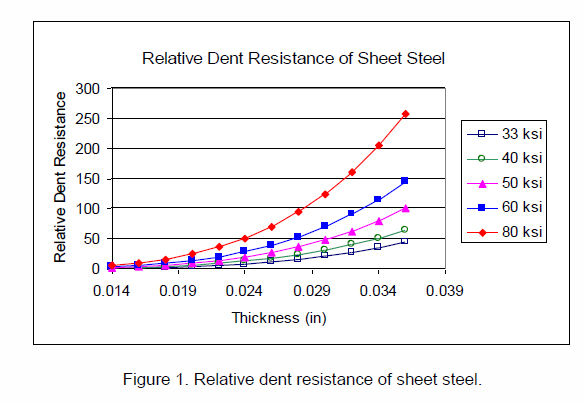

Figure 1 shows the approximate relative dent resistance of various sheet products. For this plot, the relative dent resistance of a given coated sheet steel was calculated by varying the yield strength and sheet thickness in comparison to the dent resistance of a steel sheet with 33ksi (ksi=1000psi) yield strength and 0.014 inch of thickness. Increasing the sheet thickness has a significant effect on increasing dent resistance at higher yield strengths.

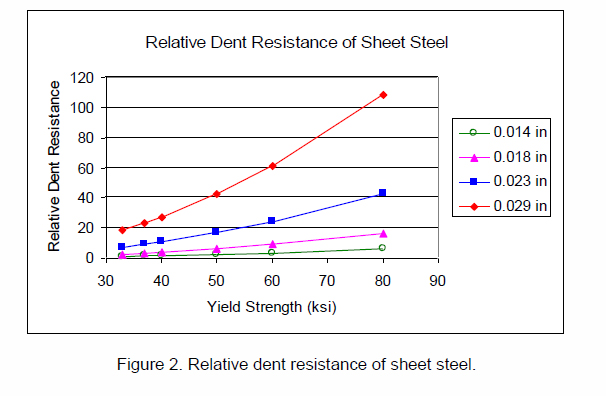

GALVALUME • Coated Sheet Steel is offered in a number of strength levels or grades. Common ASTM designations for the construction industry are Commercial Steel (CS) Types A and B, Forming Steel (FS), and Structural Steel Grades 33, 37, 40, 50 and 80. GALVALUME Sheet Steel may be temper passed and/or tension leveled to improve sheet shape and surface finish. Grade 80 product, full hard steel, has the highest yield strength among the various sheet products for metal roofing applications. Figure 2 plots the effect of strength level on dent resistance at four common thickness of coated sheet steel, 0.0142”, 0.018”, 0.023”, 0.029”, which shows that one of the most effective ways to further increase the dent resistance of the Grade 80 product is to increase its thickness.

While there are no entirely hail-proof roofs, there are multiple metal roofing systems that reduce the likelihood of cosmetic and functional damage from hail impact. Reach out to the metal roofing experts at Worldwide Steel to discuss your options for hail resistant roofing and get a head start on avoiding insurance claims.